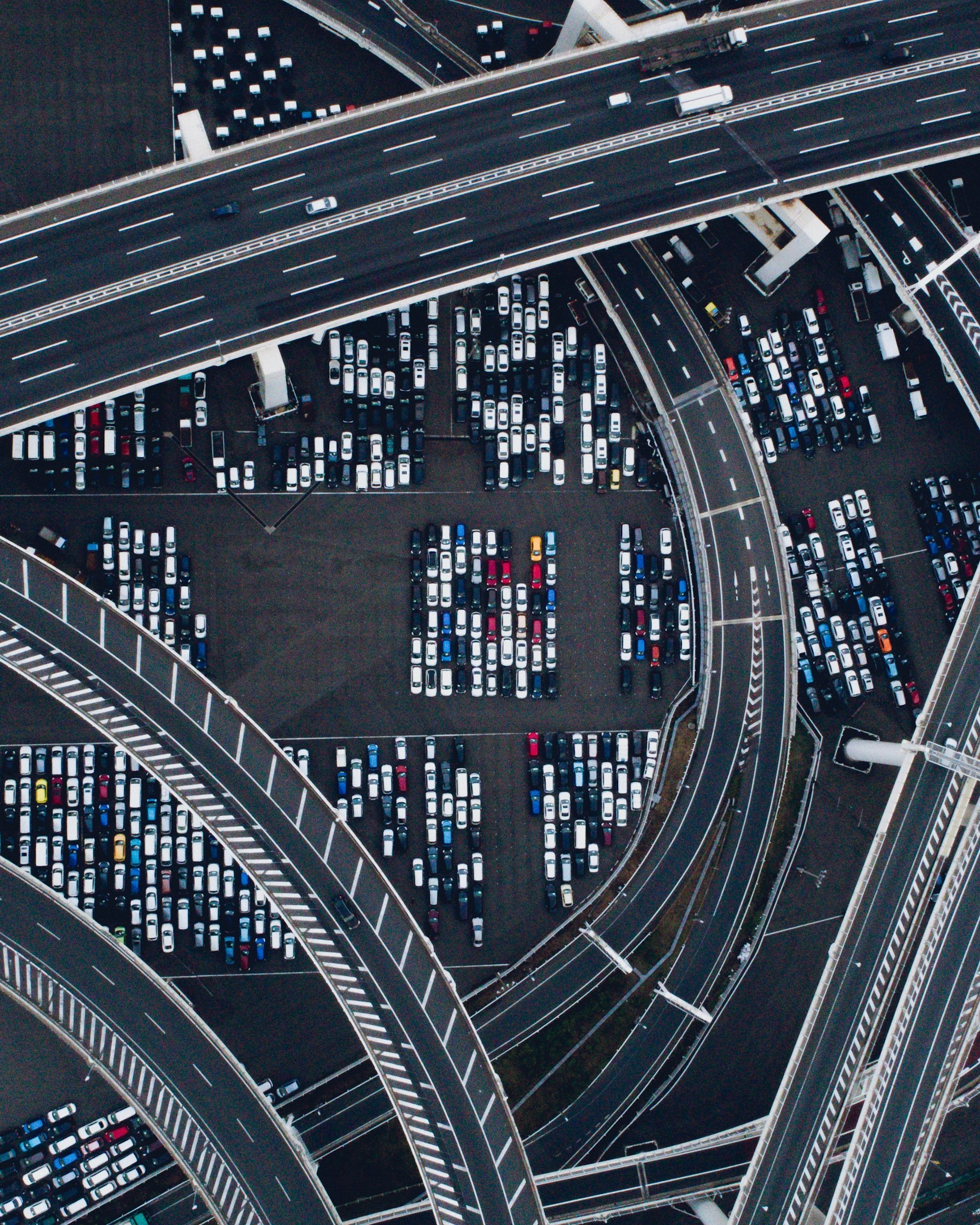

How Circular Supply Chains Are Shaping the Future of the Automotive Industry

Photo by Shot On DJI on Unsplash

The Transformation of Automotive Supply Chains

The automotive industry is undergoing a profound transformation as it embraces circular supply chains. This shift is driven by a mix of environmental urgency, economic incentive, regulatory mandates, and the rise of electric vehicles (EVs). Instead of the traditional “take-make-dispose” approach, manufacturers are now focusing on maximizing resource efficiency, reducing waste, and keeping materials in use for as long as possible through recycling, remanufacturing, and reuse [1] , [3] .

What Is a Circular Supply Chain in Automotive?

A circular supply chain in automotive refers to the integration of circular economy principles into every stage of a vehicle’s life cycle. This means designing vehicles for durability and easy disassembly, recovering and reusing valuable parts from end-of-life vehicles (ELVs), and reintegrating materials back into new production. The aim is to drastically reduce dependency on virgin raw materials and minimize environmental impact [1] , [2] .

Key Drivers: Why Circularity Now?

Several factors are accelerating the adoption of circular supply chains in automotive:

- Environmental and Regulatory Pressure : Governments worldwide, especially in Europe and Asia-Pacific, are tightening regulations on vehicle waste, recycling, and carbon emissions. For example, the EU End-of-Life Vehicles Directive taking effect in 2026 will require higher use of recycled materials in new cars, forcing automakers to adapt [2] .

- Resource Scarcity and Cost : The scarcity of critical minerals (like lithium, cobalt, and nickel) for EV batteries is pushing manufacturers to secure supply through recycling and recovery initiatives, lowering reliance on mining and reducing costs [1] .

- Market Opportunity : According to BIS Research, the automotive circular economy market is expected to more than triple by 2034-from $153.63 billion in 2024 to $455.33 billion, with a compound annual growth rate (CAGR) of 11.48% [3] , [5] .

- Technology Innovation : Digitalization, advanced tracking, and green manufacturing technologies are enabling better resource management, transparency, and efficiency in automotive supply chains [1] .

Core Strategies in Circular Supply Chains

Success in circular supply chains depends on implementing several core strategies:

- Design for Disassembly and Material Recovery : Automakers are redesigning vehicles to make it easier to recover and recycle parts at the end of a vehicle’s life. This involves using standardized components, modular designs, and materials that are easier to separate and process [1] .

- Remanufacturing and Refurbishment : Instead of disposing of used parts, companies can remanufacture engines, transmissions, and electronics to meet “as-new” standards, reducing the need for new resources and lowering costs. Deloitte notes that margins from remanufactured parts can reach 15-20% [2] .

- Recycling and Material Recovery : Robust recycling networks are crucial for recovering metals, plastics, and rare earths. For example, battery recycling initiatives are helping ensure a steady supply of critical minerals for EVs [1] , [5] .

- Product-as-a-Service and Sharing Platforms : The rise of car sharing and mobility services transforms ownership models, extending product lifecycles and spreading the environmental impact over more users [4] .

- Strategic Partnerships : Automakers are forming alliances with recyclers, chemical companies, and digital innovators to access expertise, infrastructure, and recycled materials [2] .

Implementation: Step-by-Step Guidance

For automotive businesses aiming to transition toward circular supply chains, the following steps can provide a practical pathway:

- Assess Current Supply Chain : Evaluate existing logistics, procurement, and production processes for circular potential. Identify waste streams, material flows, and opportunities for recovery or reuse.

- Engage Stakeholders : Involve suppliers, logistics partners, recyclers, and customers early in the process. Build a network focused on shared sustainability goals.

- Pilot Circular Initiatives : Launch pilot projects in areas with high impact, such as battery recycling, remanufacturing of components, or design changes for easier disassembly.

- Invest in Technology : Adopt digital tracking, blockchain for materials provenance, and advanced manufacturing techniques to increase transparency and efficiency.

- Monitor and Scale : Measure performance using KPIs (e.g., percentage of recycled content, waste reduction, cost savings). Refine strategies and expand successful pilots across the organization.

For businesses seeking detailed guidance or regulatory compliance resources, consult your national automotive industry association or search for “automotive circular economy resources” on the official websites of leading organizations such as the European Automobile Manufacturers’ Association (ACEA) or the U.S. Environmental Protection Agency (EPA).

Real-World Examples and Case Studies

Several leading automakers are already reaping the benefits of circular supply chains:

- Volvo has committed to making its vehicles from at least 25% recycled plastics by 2025 and is investing in battery recycling for its electric vehicles.

- Renault operates the “Re-Factory,” a dedicated site in France for refurbishing, remanufacturing, and recycling vehicles and components.

- North American automakers are pioneering initiatives in battery repurposing and the use of recycled materials, with regulatory frameworks supporting these innovations [5] .

Potential Challenges and Solutions

While the opportunities are substantial, businesses face several challenges:

Photo by Hunt Han on Unsplash

- Complex Supply Chains : Managing reverse logistics and tracking materials across multiple cycles can be difficult. Adoption of digital technologies and partnering with logistics experts can help overcome these hurdles.

- Quality Assurance : Ensuring remanufactured or recycled parts meet strict safety and performance standards is essential. Industry certifications and transparent testing protocols are key.

- Regulatory Compliance : Requirements vary widely between regions. Stay informed by monitoring updates from official bodies such as the European Commission or your local regulatory agency.

- Change Management : Transitioning to circular models requires cultural and organizational shifts. Investing in workforce training and building a sustainability-focused company culture can ease the transition.

Alternative Approaches and Additional Resources

While full circularity may not be immediately feasible for every business, alternative approaches can provide incremental benefits:

- Partial Circularity : Start with recycling particular components or piloting remanufacturing in select product lines.

- Supplier Collaboration : Work with suppliers to increase the recycled content in purchased materials.

- Third-Party Partnerships : Leverage external expertise by partnering with established recycling or remanufacturing firms.

To access resources, you can:

- Contact your national automotive industry association for best practice guides and local case studies.

- Search for “circular supply chain automotive” on reputable industry platforms or regulatory agency websites.

- Attend industry conferences that focus on sustainability and innovation in automotive supply chains.

Key Takeaways

The future of circular supply chains in the automotive industry is unfolding rapidly, presenting both significant opportunities and new challenges. By prioritizing resource efficiency, embracing innovative business models, and forming strategic partnerships, automotive businesses can unlock new revenue streams, mitigate risks, and ensure long-term competitiveness. Staying informed and proactive-through research, partnerships, and compliance-will be crucial for success in this new era.

References

- [1] Mayco International (2024). Exploring Sustainable Auto Industry Supply Chain Trends.

- [2] Deloitte (2024). Circularity in the Automotive Industry.

- [3] MarketResearch.com (2024). How the Automotive Circular Economy is Accelerating Sustainable Innovation.

- [4] Accenture (2024). Automotive’s Latest Model: Redefining Competitiveness Through the Circular Economy.

- [5] GlobeNewswire (2025). Automotive Circular Economy Industry Outlook 2025-2034.

MORE FROM ismath.net