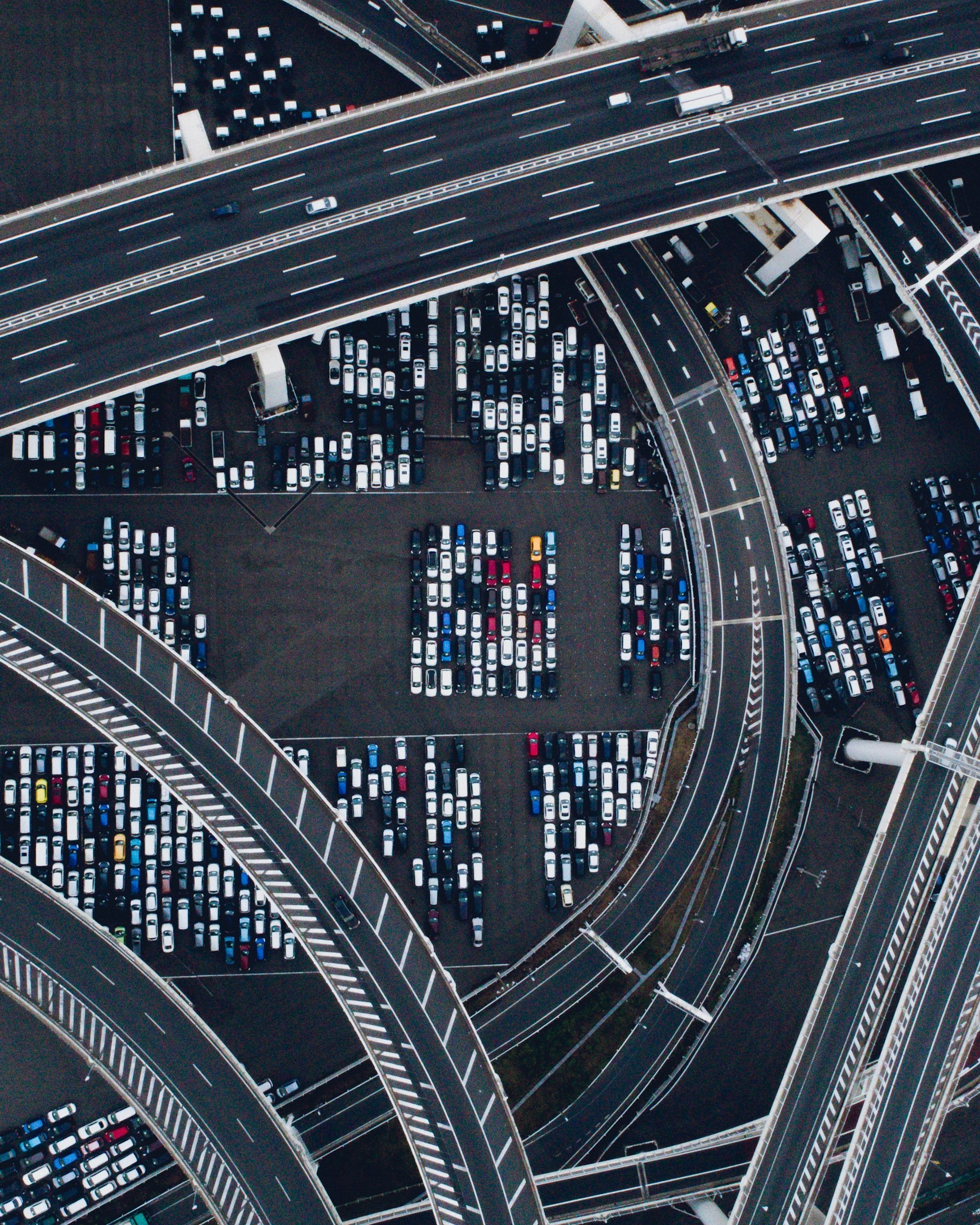

Driving Sustainability: The Transformative Impact of the Circular Economy on the Automotive Sector

Photo by Markus Winkler on Unsplash

Introduction: Rethinking the Automotive Lifecycle

The automotive sector stands at a pivotal crossroads. Traditionally built on a linear economy-where vehicles are produced, used, and ultimately scrapped-the industry is undergoing a profound transformation. The shift toward a circular economy is redefining how cars are designed, manufactured, utilized, and recycled. This transition is not only driven by mounting environmental pressures but also by economic incentives, regulatory changes, and evolving consumer expectations. [1]

Understanding the Circular Economy in Automotive Manufacturing

In the context of automotive manufacturing, the circular economy is a model that prioritizes minimizing waste and maximizing resource use at every stage of a vehicle’s lifecycle. Unlike the traditional “take-make-dispose” model, circularity focuses on:

- Designing for durability : Ensuring vehicles and components are built to last and can be easily disassembled for repair or reuse.

- Repair, refurbishment, and remanufacturing : Extending the useful life of vehicles and their parts through systematic repair and upgrading.

- Recycling and reintegration : Recovering materials from end-of-life vehicles (ELVs) and reintroducing them into the manufacturing cycle. [2]

This holistic approach spans the entire automotive value chain-from raw material sourcing and design to production, use, and end-of-life management. [5]

Key Benefits of the Circular Economy for the Automotive Sector

Adopting circular economy principles offers a range of benefits for the automotive industry:

Reduced Environmental Impact

One of the most significant advantages is the reduction of environmental harm. By utilizing recycled materials, minimizing waste, and improving resource efficiency, manufacturers can substantially lower their carbon footprint and dependence on finite resources. [2] For example, using recycled metals in car manufacturing cuts down on mining and energy-intensive processing, while the repurposing of electric vehicle (EV) batteries for second-life applications reduces hazardous waste. [3]

Economic Value and Cost Savings

The circular economy is not just an environmental imperative-it is also a growing market. According to research, the global automotive circular economy market is projected to expand from $153.63 billion in 2024 to over $455 billion by 2034 , representing a compound annual growth rate (CAGR) of more than 10%. [1] This growth is fueled by the rising demand for recycled, remanufactured, and refurbished car parts, as well as lower operating costs achieved through resource efficiency and waste reduction. [3]

Regulatory Compliance and Risk Management

Governments, particularly in Europe and Asia-Pacific, are enforcing stricter regulations on vehicle design, waste, and recycling. The European Union, for example, is introducing new rules that require carmakers to use a minimum amount of recycled materials in new vehicles, make vehicles easier to dismantle, and take responsibility for collecting and treating ELVs. [4] Compliance with these laws not only helps companies avoid penalties but also enhances their sustainability credentials and market competitiveness.

How Car Manufacturers Are Adopting Circular Economy Practices

Implementing a circular economy requires coordinated action throughout the entire vehicle lifecycle. Key steps include:

1. Sustainable Design and Engineering

Car makers are increasingly designing vehicles with modular components that can be easily removed, repaired, or upgraded. This enables longer product lives and facilitates recycling at end-of-life. [5] Leading manufacturers are using eco-design tools and life-cycle assessments to minimize environmental impact from the outset.

2. Use of Recycled and Renewable Materials

Automakers are boosting the use of recycled plastics, metals, and composites in vehicle production. For example, some companies now use carpets, seats, and dashboards made from recycled ocean plastics or industrial waste. This not only reduces resource extraction but also creates new business opportunities in recycling and material supply.

3. Remanufacturing and Refurbishing Components

Many OEMs now offer remanufactured engines, transmissions, and other critical parts as a standard offering. These components are restored to like-new condition, saving both materials and energy compared to producing new parts from scratch. Repair and refurbishment services are becoming more accessible through authorized dealer networks and specialized recycling centers.

4. Closed-Loop Recycling Systems

Manufacturers are investing in systems that capture materials from ELVs, sort them efficiently, and reintegrate them into new vehicles. This closed-loop approach helps ensure valuable resources remain in circulation and reduces reliance on virgin materials. [2]

5. Second-Life Applications for Batteries and Electronics

With the surge in electric vehicles, battery reuse and repurposing have become central to circular strategies. Used EV batteries can be redeployed for stationary energy storage or industrial applications, extending their value and reducing e-waste. [3]

Real-World Examples and Case Studies

Several leading automotive manufacturers are already demonstrating the benefits of the circular economy:

- Renault operates the “Refactory” facility in France, where vehicles and parts are refurbished, remanufactured, and recycled at scale. This initiative has significantly reduced waste and created new revenue streams.

- BMW and Volkswagen have launched pilot projects to recover and reuse EV batteries, exploring partnerships with energy providers and recycling firms.

- In the United States, several plants now use closed-loop aluminum recycling, dramatically lowering both emissions and raw material costs. [1]

Accessing the Benefits: Practical Steps for Businesses and Consumers

If you are an automotive manufacturer, supplier, or consumer interested in participating in or benefiting from the circular economy, consider these actionable steps:

- For manufacturers: Invest in eco-design tools, partner with certified recycling facilities, and explore remanufacturing programs. Engage with industry groups and regulatory bodies to stay current with evolving standards. You can find sector-specific support by searching for “automotive circular economy” and your region’s main industry association or environmental agency.

- For suppliers: Consider developing services in recycling, refurbishment, or second-life component supply. Engage with automakers to integrate your solutions into their supply chains.

- For consumers: Opt for vehicles and replacement parts labeled as recycled, remanufactured, or refurbished. Ask your dealership about trade-in, refurbishment, or recycling services at end-of-life. Many major automakers offer buy-back or recycling programs-contact their official customer service channels for details.

- If you want to learn more about current regulations (such as those in the EU), visit the official European Parliament website and search for “automotive circular economy rules.” For U.S. developments, check resources from the U.S. Environmental Protection Agency (EPA) and Department of Energy (DOE) for guidance on recycling and sustainable vehicle practices.

Challenges and Solutions in Implementation

While the opportunities are substantial, challenges remain. Adapting production lines, ensuring a steady supply of recycled materials, and meeting regulatory requirements can require significant investment. There are also logistical hurdles in collecting and processing ELVs efficiently. Companies are overcoming these barriers by forming industry consortia, investing in new recycling technologies, and working closely with regulators to streamline compliance.

Alternative Approaches and Future Trends

Some manufacturers are exploring product-as-a-service models, leasing vehicles instead of selling them outright. This allows companies to retain ownership and responsibility for end-of-life processing, facilitating refurbishment and recycling. Digital technologies such as IoT tracking and blockchain are also being piloted to improve traceability and ensure authenticity in recycled parts.

As new regulations take effect and consumer demand for sustainability grows, expect further innovation in materials science, logistics, and business models. Companies staying ahead of these trends will be best positioned for long-term success.

Summary: Embracing the Circular Future

The circular economy is rapidly becoming a defining force in the automotive sector. By embracing principles of sustainability, resource efficiency, and innovation, car manufacturers and stakeholders can achieve significant environmental and economic gains. Businesses and consumers alike can participate in this transformation by prioritizing recycled materials, supporting refurbishment initiatives, and staying informed about the latest regulatory and industry developments.

Photo by Shot On DJI on Unsplash

For further information, search for your country’s main environmental agency or automotive association and explore their latest guidance on sustainable mobility and circular economy initiatives.

References

- [1] MarketResearch.com (2024). How the Automotive Circular Economy is Accelerating Sustainable Innovation.

- [2] Shoplogix (2024). Circular Economy in Automotive Manufacturing.

- [3] InsightAce Analytic (2024). Automotive Circular Economy Market Size, Share, Growth.

- [4] European Parliament (2025). New EU rules on design, reuse and recycling in the automotive sector.

- [5] ARC Advisory Group (2024). Automotive Industry Embraces the Circular Economy.

MORE FROM ismath.net